Cutting The Guesswork From Tire Development

Wheel Energy’s mechanical tire tests cut the guesswork from tire development.

Specialized decided a couple years ago that its tire line needed to improve. The cycling industry titan based in Northern California produces a rainbow of products—frames, shoes, helmets and other accessories—that are widely considered to be among the best in the industry. But, according to Specialized, tire quality lagged.

To address this rare shortcoming, Specialized brought in Wolf Vorm Walde, a specialist with years of experience designing bike rubber, and charged the German tire maven with elevating tire quality to match the rest of their line.

PHOTOS: Behind The Scenes With Wheel Energy

One of Vorm Walde’s first moves was to integrate unbiased, third party tire testing into the design and development process. Mechanical testing can be used to unequivocally quantify tire performance instead of relying on subjective analysis. To accomplish this goal, he turned to Wheel Energy (Wheelenergy.com), an ATV and bike tire testing company housed in a rectangular building in the Finnish countryside. Behind abandoned farm equipment and a pile of firewood, their facility houses several home-cooked machines that can measure the puncture resistance, rolling resistance and cornering grip of cycling tires.

One of the first things Specialized learned after sending its tires to Wheel Energy: Its then top-of-the-line tire rolled like a brick compared to premier tires from other makers. Specialized admits they had a lot of work to do to improve the quality of their race rubber, but Wheel Energy’s tire tests provided Specialized with the tools to do so.

Why laboratory tire testing?

At first glance, the job of a bike tire appears pretty simple. It must hold air and prevent punctures, and if it’s light, that’s a bonus. We triathletes are so focused on aerodynamics—wheels, tires, frames, position and even water bottles—that the performance value of a tire can be easily forgotten. In reality, the tire casing and rubber both have a massive influence on ride comfort, dependability and even the straight-line speed of the entire bike.

Wind tunnels have become an indispensible tool in the development of aerodynamic bike equipment because they quantify wind drag. Instead of speculating about the aerodynamic characteristics of a component or frame, a wind tunnel can precisely measure its wind resistance. Mechanical laboratory tests can do the same for tire performance. By measuring a tire’s flat resistance, cornering performance and rolling resistance by simulating road conditions inside a lab, these tests can eliminate guesswork from tire development.

Rolling resistance

How it’s tested

To measure rolling resistance, Wheel Energy presses a tire against a smooth, nearly cylindrical metal drum and turns the wheel with a specific amount of power, then measures the speed of the wheel. All other variables are controlled so rolling resistance between the tire and the drum is the only thing affecting wheel speed. Measuring that speed allows Wheel Energy to calculate the coefficient of rolling resistance of various tires.

What matters?

It was long assumed that narrow tires have less rolling resistance than wide tires, but that is in fact not true—Wheel Energy found that a 25c tire has 5 percent less rolling resistance than an identically constructed 23c tire. Many people also believe that a tire’s casing—the structural foundation of the tire—made with finer threads creates less resistance than one constructed with thicker threads. This is also incorrect.

From the lab to the road

Rolling resistance is arguably the most important characteristic of a triathlon race tire since it directly affects straight-line speed. To reduce rolling resistance, Specialized removed material from the shoulder of the tires, changed the tread and rubber composition and reduced the casing rubber thickness. Through these changes, Specialized was able to reduce the rolling resistance of the S-Works Turbo by an astonishing 25 percent compared to their top-flight tire from 2010. According to Specialized, it is competitive with the fastest tires from any other brand.

Puncture resistance

How it’s tested

The second most important attribute of a tri race tire, in our opinion, is puncture protection. To measure a tire’s puncture resistance, Wheel Energy presses a small dowel into the tire with increasing force until it punches through and flats the tire, then records the force required to break through.

What matters?

Specialized was able to test the effectiveness of various types of puncture resistant layers to evaluate their effectiveness. These layers also tend to increase rolling resistance. Specialized found that tire casings with larger threads (low TPI) tend to be more puncture resistant than those built with thinner threads.

What changes?

The test for puncture protection reveals that tires with moderate TPI count are resilient to flats. The rolling resistance test shows that tires with such casing also have low coefficients of rolling resistance. The results of Specialized’s tests reveal that this style of tire, not a tire with ultra-high TPI, is best suited to the specific needs of triathletes.

Cornering Grip Test

How it’s tested

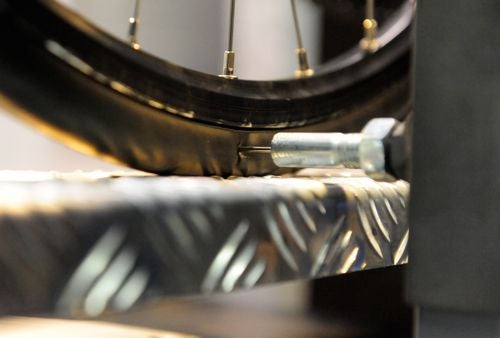

To test cornering grip, Wheel Energy takes a slab of asphalt and mounts it at a 45-degree angle on top of a wooden block.

The tire in question is mounted onto a wheel and inflated to a fixed pressure with an automatic inflation device that precisely sets the tire pressure, eliminating the possibility that human error screws with the results. Once the tire is inflated, it is pressed into the angled slab of pavement with a specific amount of force, also controlled by the test machine, and dragged against the road-like surface while recording the force on the tire. Force increases steadily until the tire looses purchase and starts to slide. By recording the amount of force needed to slide the tire across the pavement under highly controlled conditions—tire pressure, force on the tire and road surface are all identical in all tests—Wheel Energy is able to quantify and rank the cornering grip of various tires.

What matters?

Tire compound, the type of rubber used, is the most important factor. “We did not isolate things like casing influence and puncture belt influence. We picked the compound for the Turbo and a different one for the Roubaix,” describes Vorm Walde.

From the lab to the road

“The Turbo has lower rolling resistance and is a little softer but it’s not as resistant to cuts. Roubaix is more cut resistant, and is also more abrasion-resistant (has a slower wear rate). It is a little slower and feels a little harder subjectively [than the Turbo],” says Vorm Walde.

Adhesion Test

How it’s tested

Wheel Energy measures a tire’s straight-on grip by pressing it into a slab of stone or pavement and pulling on it until the tire starts to drag across the surface. By controlling the factors other than the tire that influence grip, Wheel Energy is able to isolate the differences in grip between tires.

What matters?

The test can used to measure grip differences created by tire construction, rubber compound and tread pattern. It can be conducted in wet and dry conditions.

From the lab to the road

This factor is more important for off-road tires than for road tires.

Ideal Inflation Pressure

The mechanical tests conducted in the woods of Finland reveal a tremendous amount about a tire’s characteristics, but its performance on race day also depends on its inflation pressure. “The tire can adapt [to the road], and it’s the first thing in contact with the road—it absorbs shock, it deflects little roughness instead of just giving it all to the wheel and to the rider in the end,” says Vorm Walde.

Vorm Walde compares the specificity of car tires with the ability to alter the pressure in your cycling tires. “You see a certain model tire on a BMW and on an Audi, but it’s never the same tire. The name is the same, it’s the same model but Audi has different specifications for the same tire because the [car’s] suspension geometry is different, so they dial in the tires a little differently. It’s dialed in to the car model, even though it’s the same tire model. They make those subtle changes to influence the ride, steering stability and driving comfort.”

Just as car manufacturers specify certain tire characteristics to complement their vehicles, cyclists must tailor inflation pressure to maximize performance and comfort based on specific race conditions, including road surface and temperature change throughout the day.

“The riders are the different car models,” clarifies Vorm Walde. “You have to adapt the model to meet the likings of the individual rider. You have to change the tire pressure to make it work for you. There is such a big span in rider weight and riding style it’s impossible to give a rule of thumb for tire pressure. It really comes down to trying it out and playing with it.”

Although Wolf says there is no rule of thumb for selecting the ideal tire pressure for an individual rider, he provides two guidelines for minimizing rolling resistance while avoiding the risk of tire explosion on a hot day.

Reduce rolling resistance: Inflating beyond 8.5 bars (123 psi) you don’t really get a significant reduction in rolling resistance. If you test a 23c or a 25c tire at 6.5 (94 psi), 7.5 (108 psi) and 8.5 bars (123 psi), you will see that rolling resistance decreases the higher the pressure gets. You also see that the savings gets [smaller and smaller] as pressure goes up. Beyond approximately 130 psi, the rolling resistance doesn’t change at all any more.

Prevent blow-outs: “You get your bike ready early in the morning, pump to 9 bars (130 psi), it sits there and warms up and maybe in the afternoon [the pressure is] 40 psi more in the afternoon.” This large increase in pressure can cause the tire to blow, especially if you ride clinchers. “It’s pretty hard to come up with a pressure in the morning, but I would recommend to pump the tires to 7.5 or 8 bars (108 or 115 psi) when it’s chilly in the morning, or if you expect a warm up of more than 10 degrees Celsius [50 degrees Fahrenheit] to account for this rise in air pressure in the tire,” recommends Vorm Walde.

Production Quality

It may seem like a given that the tires produced by overseas factories are exact replicas of the originals sent by the product designers, but differences in materials and processes directly alter the tires that actually spin on your wheels. Wheel Energy also helps Specialized vet different tire production factories and ensure that the tires sold to riders actually match the prototype.

When Specialized designs a new tire, they send models to various factories and ask the manufacturer to produce a sample. They take those samples and run them through Wheel Energy’s battery of tests to objectively judge the tires that can potentially be sold to the public. “Wheel Energy provides the resources to directly test our tires and tune the compounds for race tires. Let’s say we have a specific compound. We do the adhesion test and the rolling resistance tests [on multiple reference tires submitted by factories]. With these two tests, we can gauge the compound performance pretty well and decided which one to go with,” says Vorm Walde.

The best tires for triathlon

TPI stands for threads per inch, the quantity of threads per in used to construct the tire’s backbone, its casing. It is widely assumed that a tire with high a TPI count is better than a low TPI count, but Wheel Energy has helped Specialized find that while that may be true for some road races tires with moderate TPI count, somewhere between 60 and 120 TPI, are ideal for triathletes.

“There is a misperception,” says Vorm Walde. “60 TPI can be fast.”

Although it is true that tires with high TPI count are more supple and lighter than tires with fewer threads, suppleness and weight aren’t the most important attributes for a triathlon tire. To get from T1 to T2 as fast as possible, a tire should be designed for low rolling resistance and good puncture protection. Those two characteristics are actually facilitated by moderate a tire casing with a moderate thread count, between 60 and 120 TPI, not an ultra-high TPI tire.

Wolf says, “The Specialized Turbo Pro (120 PI) is a more appropriate tire [for triathlon] than the S-Works [Turbo Tire (220 TPI)]. The amazing thing about that statement is that the Turbo Pro is cheaper than the S-Works Turbo. If you want a very lightweight tire, 220 TPI achieves that. For all-around riding or racing, I would always go for 120 TPI at the most. [That construction] is more robust, we have weight, rolling resistance and puncture protection. The thicker the fiber, the more cut resistance. 30 TPI is the most cut resistant. With 60-120 TPI, the fibers are laid close enough that it is not so easy to stick a nail through this fabric but the fabric is cut-resistant. At 220 TPI the fibers are so thin, it’s pretty easy to cut the sidewall,” says Vorm Walde.